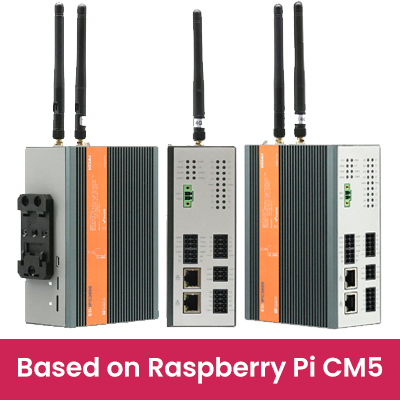

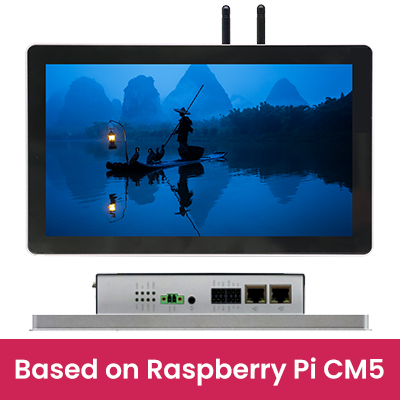

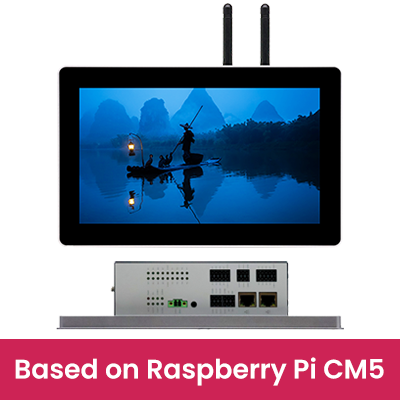

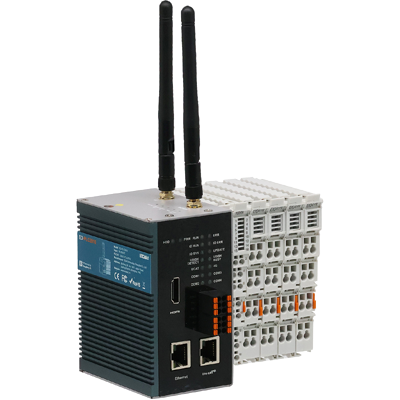

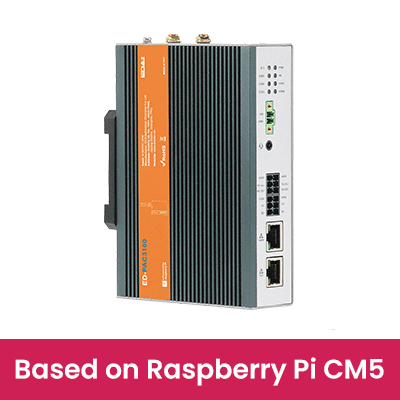

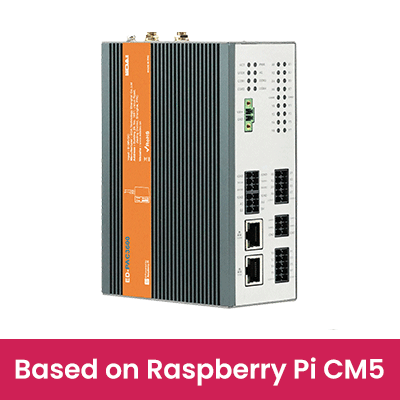

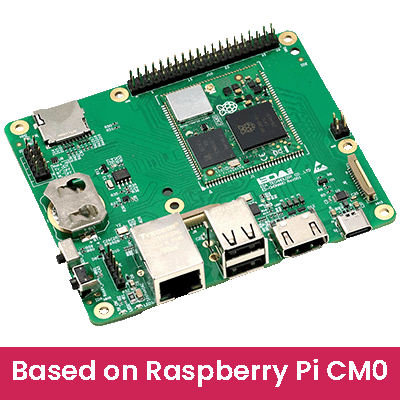

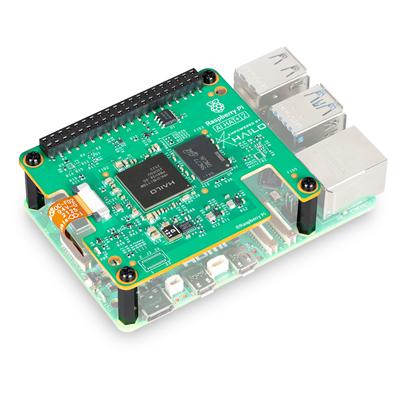

The IPC3600 Series Industrial Computers launched by EDATEC are built on the Raspberry Pi Compute Module 5 (CM5), focusing on high-end manufacturing and automation scenarios. Integrating rich industrial interfaces such as RS232, RS485, CAN bus, and digital I/O, and relying on a mature industrial software ecosystem, it provides hardware-level real-time response and integrated hardware-software control solutions for scenarios like robot control, production line synchronization, and equipment interlocking.

Broadcom BCM2712 Processor: Sufficient Computing Power for Industrial Scenarios

Precisely matching high-end industrial needs, the IPC3600’s computing core (CM5) is equipped with the Broadcom BCM2712 quad-core Arm Cortex-A76 processor, with a maximum frequency of 2.4GHz and adopting the 64-bit ARM v8 architecture.

Integrated graphics and video processing unit: GPU supports OpenGL ES 3.1 and Vulkan 1.2 standards; VPU supports H.265 (HEVC) 4Kp60 decoding.

Storage options: Available with 2GB/4GB/8GB/16GB LPDDR4-4267 SDRAM and 16GB/32GB/64GB eMMC high-speed flash memory. Two expansion methods are supported: Micro SD card or M.2 NVMe SSD (optional 128GB/256GB/512GB), offering flexible storage configurations.

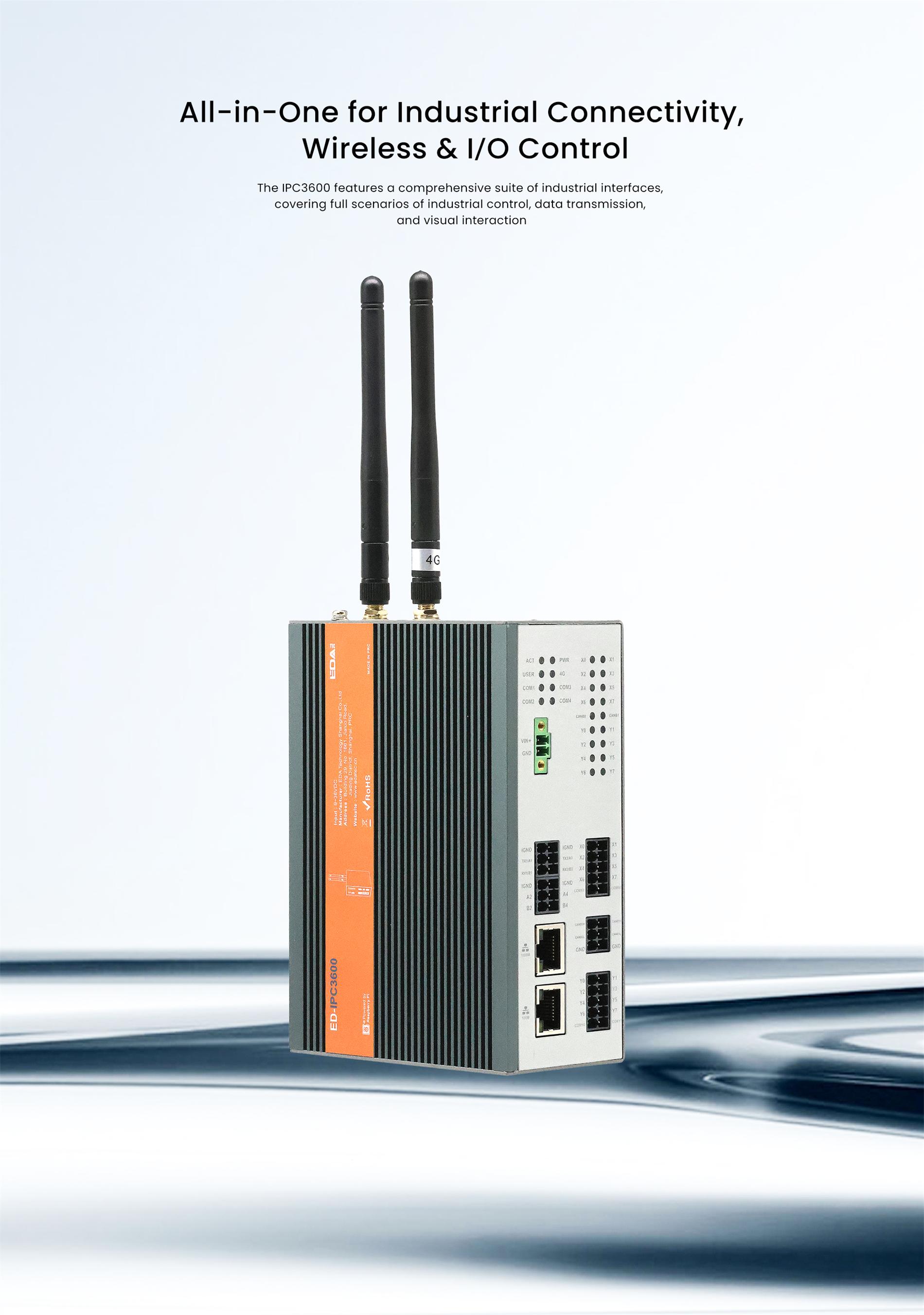

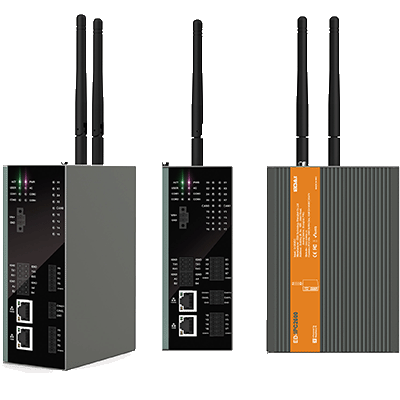

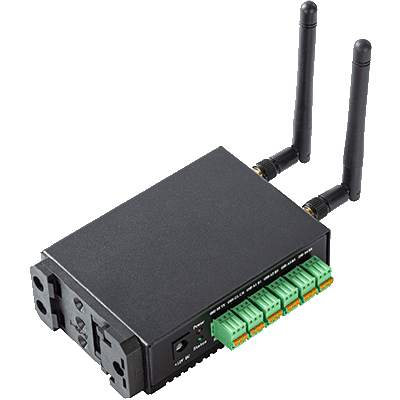

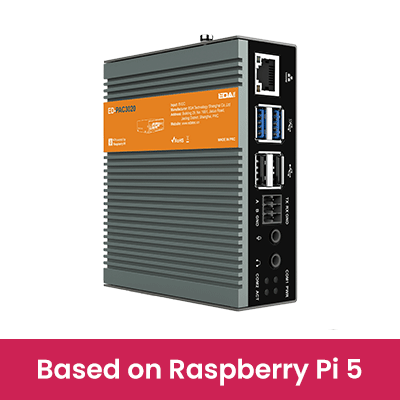

All-in-One for Industrial Connectivity, Wireless & I/O Control

The IPC3600 features a comprehensive suite of industrial interfaces, covering full scenarios of industrial control, data transmission, and visual interaction:

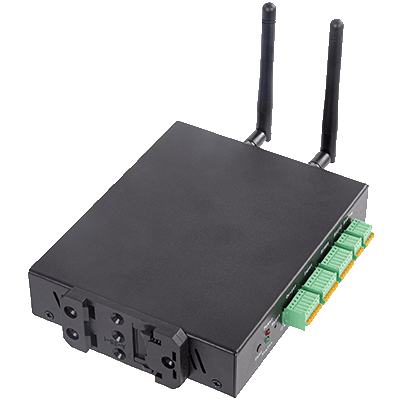

- Industrial connectivity: Configurable quantities of RS232 and RS485 ports; standard 2 x CAN 2.0B (3KV isolation protection, 10-1000kbps baud rate).

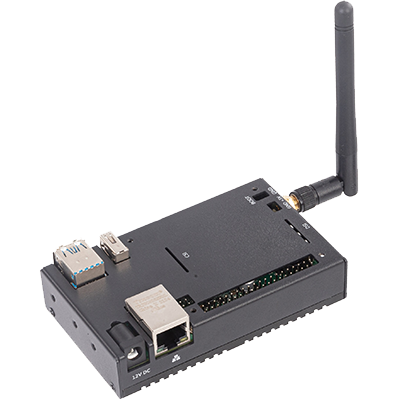

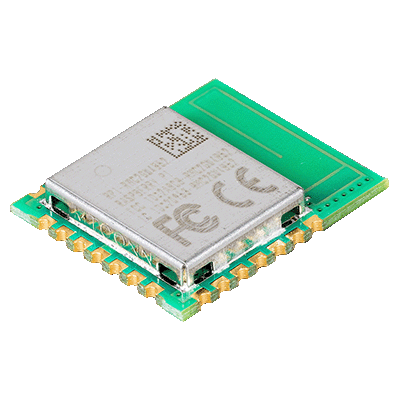

- Wireless connectivity: Optional dual-band Wi-Fi and Bluetooth 5.0 module for remote debugging; 4G LTE module (with GNSS integration for some models) expandable via Mini PCIe interface.

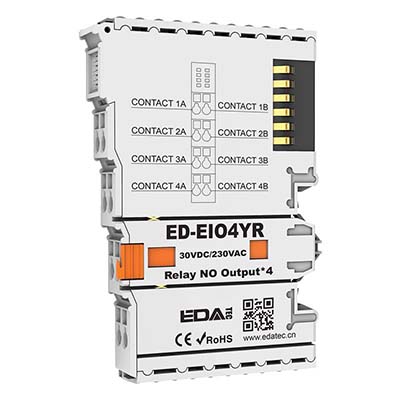

- Digital I/O: 8-channel isolated DI + 8-channel isolated DO, supporting wet/dry contact input, directly driving relays and connecting photoelectric switches.

- Universal interfaces: 1 Gigabit Ethernet port, 1 Fast Ethernet port, 2 USB 2.0 ports, and 1 HDMI 2.0 port.

Wide Temperature & Voltage Range for Industrial Adaptability

CE and FCC certified, the IPC3600 operates and stores within a temperature range of -25℃~60℃, with a wide input voltage of 9V~36V (equipped with overcurrent/overvoltage/reverse polarity protection) to withstand industrial power grid fluctuations.

Structural design: Fanless passive cooling with a three-layer thermal structure (metal case + heatsink + thermal silica gel) ensures excellent heat dissipation and uncompromised CPU performance.

High-Reliability Design for Stable Operation

Dual RTC power backup: Integrates a 1F supercapacitor for RTC backup; users can install an additional battery for dual protection, keeping the system clock intact even when the device is powered off.

Isolation protection: RS232/RS485/CAN/DI/DO ports are all equipped with isolation protection to avoid signal crosstalk.

Leverage Raspberry Pi Ecosystem to Lower Development Barriers

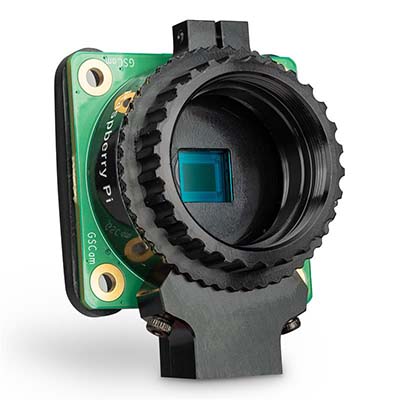

Compatible with Raspberry Pi OS (Desktop/Lite 64-bit) and fully supporting the Raspberry Pi GPIO ecosystem, the IPC3600 provides developers with a flexible and open secondary development environment. Using languages like Python and C++, developers can easily access open-source libraries such as OpenCV and NumPy to quickly implement customized functions like machine vision inspection and data collection/analysis.

Collaborate with CODESYS for Integrated Industrial Control Solutions

EDATEC has established a deep strategic partnership with CODESYS, with all IPC products fully compatible with CODESYS and offering end-to-end support from authorization to application. The IPC3600 can be pre-installed with the CODESYS runtime environment upon request. With this pre-installation, the device achieves full compatibility with the five programming languages specified in the IEC 61131-3 standard (LD/FBD/ST/IL/SCL), and supports industrial protocols including EtherCAT Master, Modbus TCP Master, and OPC UA Server, realizing seamless integration with enterprises’ existing MES and SCADA systems.

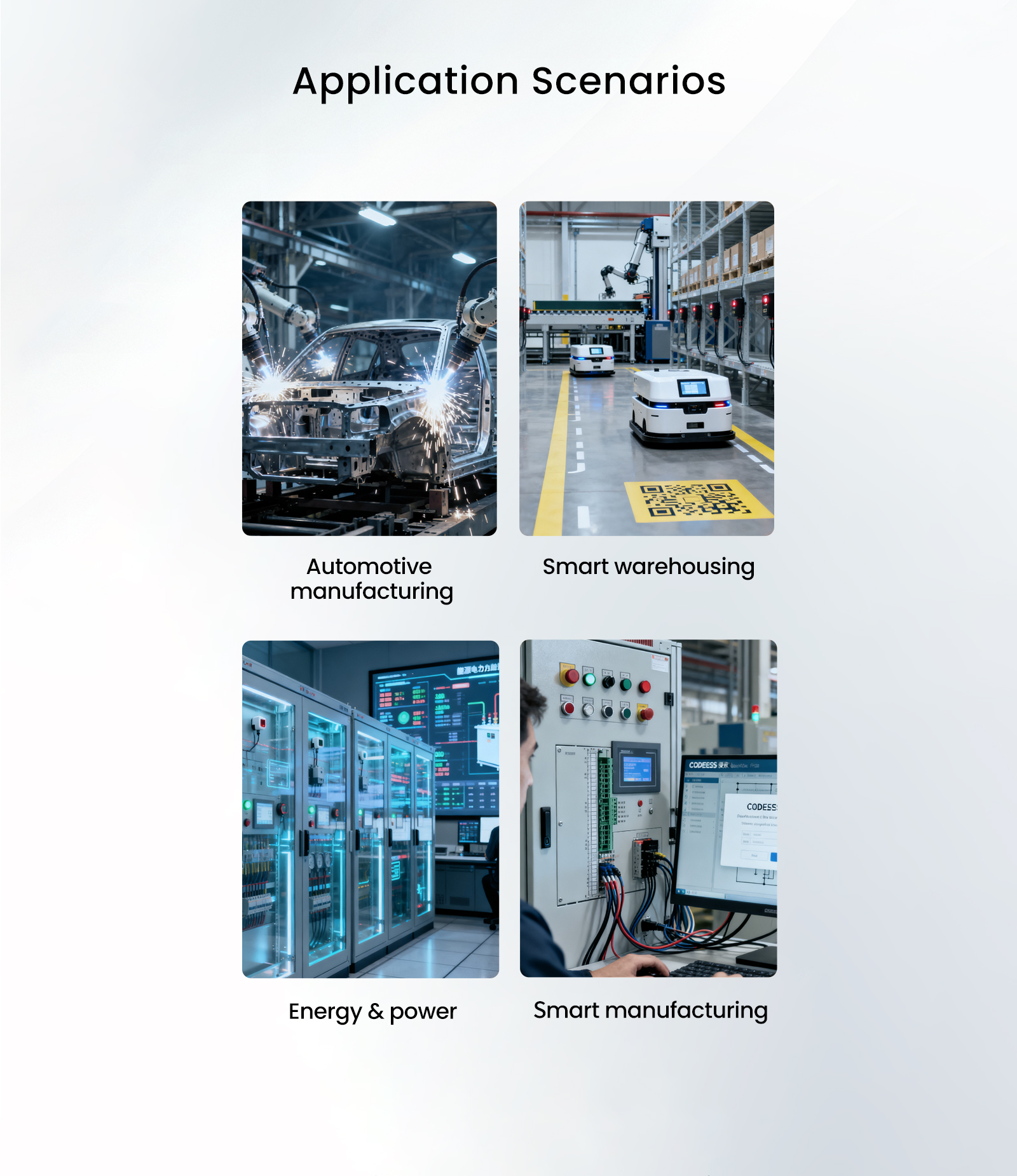

Application Scenarios

- Automotive manufacturing: CAN bus synchronization for welding robots.

- Smart warehousing: AGV scheduling and DI/DO interlocking control for photoelectric sensors.

- Energy & power: Real-time collection and monitoring of distribution cabinet equipment status.

- Smart manufacturing: Seamless replacement and upgrade of traditional PLC systems (requires CODESYS authorization).

En

En